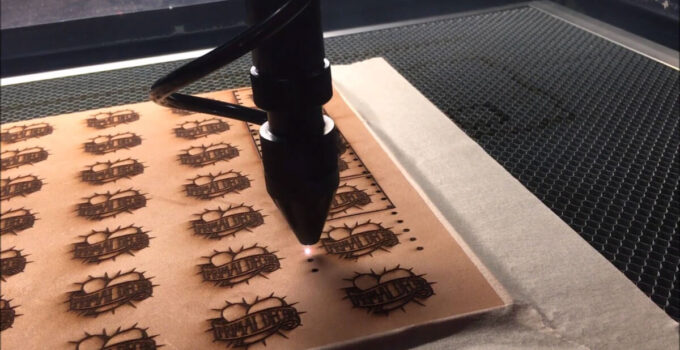

Leather laser cutting uses a powerful laser beam on the leather material. This light beam is used for engraving and cutting intricate patterns and designs into the material.

These laser cutters eliminate dross formation and striations because of manual laser cutting by reducing mechanical impact energy.

Also, a Co2 laser can eliminate the carbonization effect on leather cutting compared to the traditional procedure. Many industries use a leather laser cutter to produce different goods like shoes, bags, clothes, and decorative items.

How To Effectively Use This Kind Of Leather Laser Cutter

Source:pinterest.com

Leather laser cutter offers various features that make these machines super beneficial for the leather cutter.

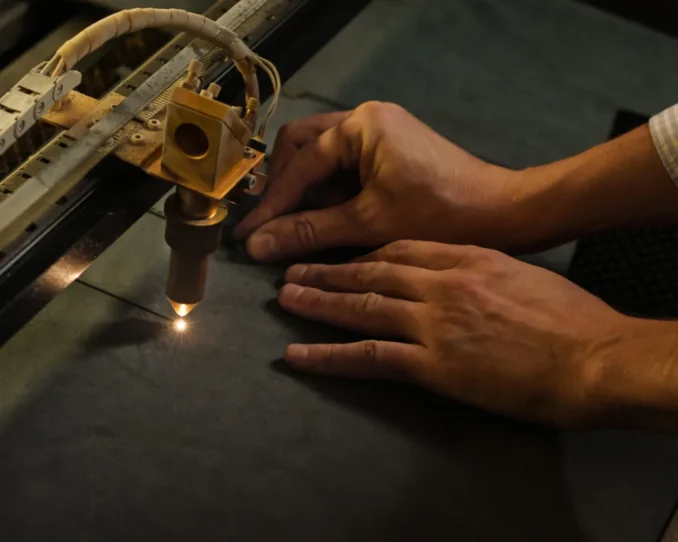

Non-Contact Processing

The most important feature of a laser cutter is that it’s a non-contrast process. This means there is no physical contact between the machine and the leather that keeps the leather in good condition. Therefore, a laser cutter works best for delicate leather.

Higher Precision and Detail

It also offers precise results and allows you to create detailed designs. You can easily create custom shapes, intricate designs, and small details with a leather laser cutter.

Higher Efficiency and Cost Savings

This amazing machine helps to eliminate human errors and gives you faster results. You can always save money by preventing leather waste with a laser cutter.

Top-Notch Quality

You will get amazing results if you invest in a high-quality leather laser-cutting machine. Of course, results greatly depend on the thickness and type of material. But the machine will impact the results.

Tips to Improve the Efficiency of the Laser Cutter

While using a laser cutter, practising with the machine before you start working on the project is best. Also, use scrap leather to select power settings and test designs to help you get a high-quality final project.

Testing every type of leather is crucial because a difference in tanning type, thickness, and finish impacts how the laser acts on the leather. Furthermore, before engraving, the leather material needs flattening. You can also use masking tape to prevent material from moving. Some people also apply masking tape to leather to protect it from soot.

Creative leather projects to try with a leather laser cutter: wallets, bags, belts, and more

Source: ponoko.com

Leather laser cutters have revolutionized the way artisans and hobbyists create leather goods, enabling the production of intricate designs with unmatched precision. With a leather laser cutter, you can explore a variety of creative leather projects that showcase your unique style and craftsmanship.

Wallets are a popular choice for laser cutting projects, as you can create personalized designs or even experiment with custom interior compartments. Additionally, you can produce bespoke bags, from clutches to tote bags, with stunning patterns and detailed cut-outs that showcase your creativity. Belts can be transformed into statement pieces with intricate motifs or personalized with names or initials.

Beyond these classic items, leather laser cutters allow you to create a wide range of accessories, such as bracelets, earrings, and keychains. Home décor items, like coasters or wall art, can be crafted with intricate patterns that add a touch of sophistication to any space. For pet lovers, laser-cut collars and leashes offer a unique way to express your furry friend’s personality.

Start Creating Leather Products On A New Level

Whether selling leather shoes or bags, you can change the game with a leather laser cutter. The leather laser cutter is designed to improve the appearance of the products. It helps you cut different types of leather in whatever shape you like. Just practice before you start using the laser cutter to get the most out of it.